- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: Shijiazhuang , Hebei, China

- Brand Name: Great Wall Equipment

- Model Number: Stainless Steel Composite Pipe Production Line

Product Description

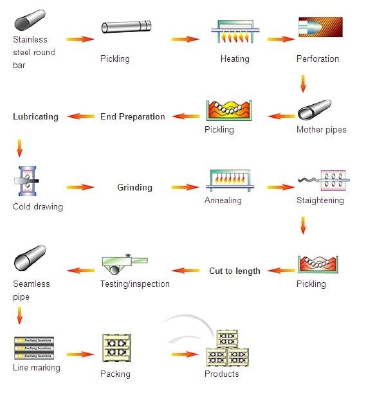

Carbon Tube Stainless Steel Composite Pipe pipe line:

Forming through mold, it is welded by duplex metal such as stainless steel and excellent carbon construction steel.

This pipe line adopts an advanced synchronous welding combination method.

Along with carbon steel pipe welding production line, synchronous welding combination method covers the surface of the carbon steel pipe with stainless steel cold belt synchronously. Through welding, sizing, straightening, length-fixing and polishing, the final pipe is produced.

The final products are within tolerance levels with high accuracy, proper package and effective performance and possess the intensity of the steel pipe and the qualities of the stainless steel pipe.

This equipment is mainly used into textile machinery, food machinery, decorating, carriages and poles in the municipal construction.

As decent, green and energy-saving material, stainless steel composite pipes have been used in the domestic national project in the past few years.

Product model number: HGBF50

Diameter: φ12-φ50mm

Wall thickness: 1 -3mm

Steel strip material: δB≤580mpa, δS≤350mpa, Mild steel & low alloy steel

Welding speed: 0-10m/min

Main motor power: 75kw

High frequency equipments: 100kw

Argon welder: 500A

Equipment composition:

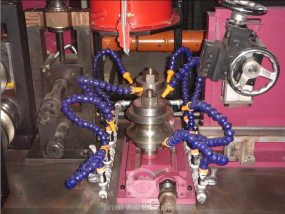

The HGBF50 Carbon Tube Stainless Steel Composite Pipe Line consists of an uncoiler, cutter & butt welder, Storing device, forming and sizing unit, Computer flying saw, discharge table, finishing polish after product line device, sack & bale machine, high frequency DC drag, argon welder product line electric appliance.

- Place of Origin: Shijiazhuang , Hebei, China

- Brand Name: Great Wall Equipment

- Model Number: Stainless Steel Composite Pipe Production Line